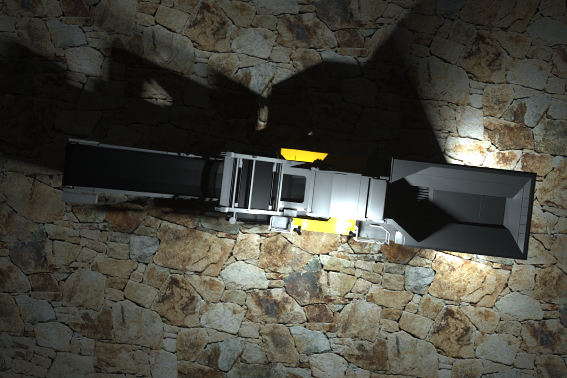

Enhanced safety and maximum convenience

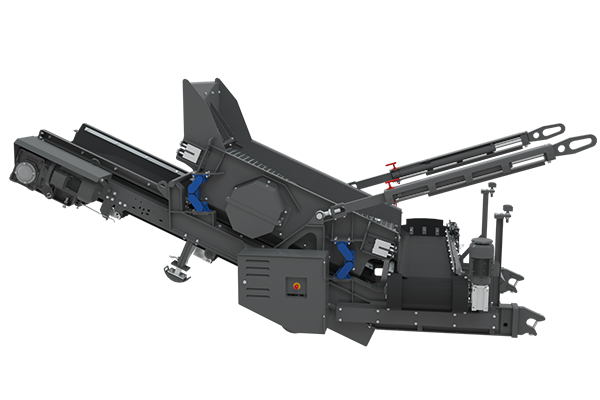

As the first NEXT philosophy crusher, the RM 120X combines maximum safety with maximum performance and flexibility. Using RM Operations Assist and RM XSMART, the crusher interacts with the machine operator who is able to see the status of the machine from the loader cab. The Performance Indicator also enables maximum efficiency in processing without leaving the cab.

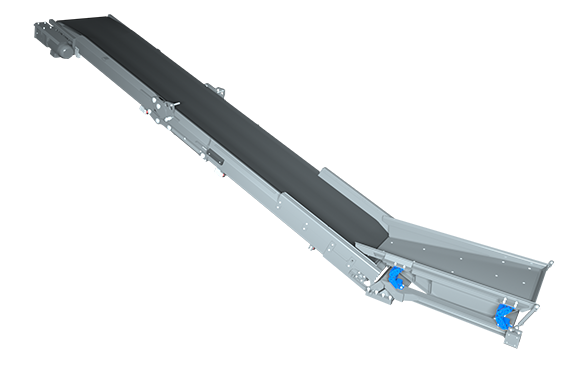

Maximum throughput capacity and maximum flexibility

The best ratio of weight to throughput capacity, combined with equipment perfectly matched to each application, guarantees maximum flexibility. Depending on the application, the RM crusher can be equipped with the optimum equipment options and drive technology. In addition, it is more efficient during operation thanks to a larger diesel tank.

Technical Data

RM 120X

| Throughput | up to 350 t/h, depending on material |

|---|---|

| Inlet opening | 1.160 x 820 mm |

| Crusher unit | RUBBLE MASTER impact crusher with 2 or 4 hammers and multi-function adjustable impact arms |

| Power unit | Diesel direct drive: John Deere, 6 cylinders, 298 kW at 2200 rpm, Maximum flexibility with hybrid drive |

| Weight (incl. magnetic separator) | 39.000 – 42.000 kg |

Download PDF

Options

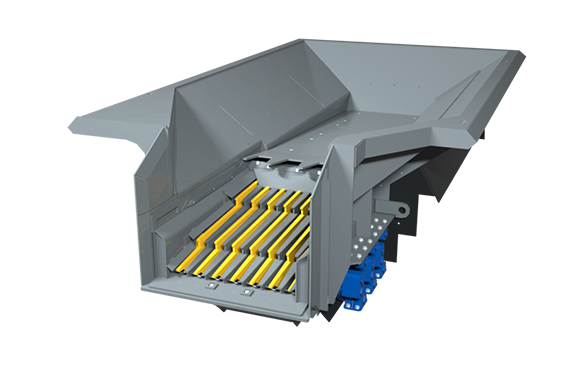

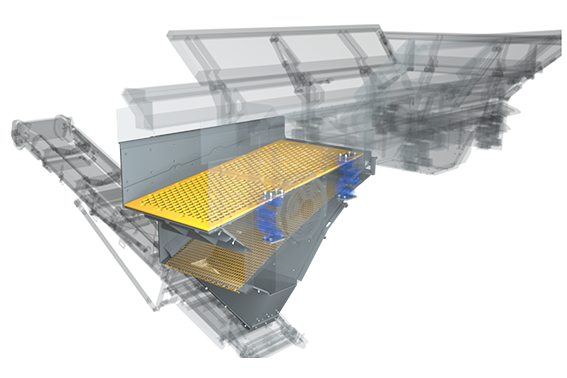

Active Prescreen 2D

Active Prescreen 2D in combination with 2-part feed belt. Due to the individually selectable mesh size and the output of a defined aggregate size, the Active Prescreen 2D is perfectly suited for use in the natural stone sector.

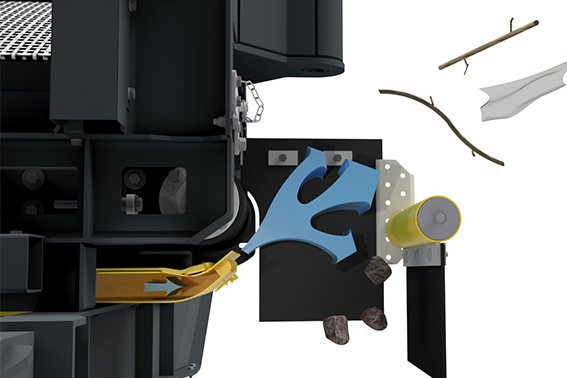

RM windsifter

The RM windsifter was developed to separate light materials from the mineral end product and thus ensure an even higher final grain quality.

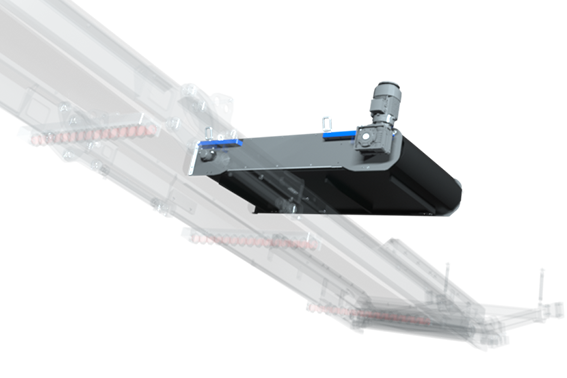

RM belt scales

The RM belt scales measure the material weight on the discharge belts and sends this data to the RM XSMART App where it can be displayed at any time.

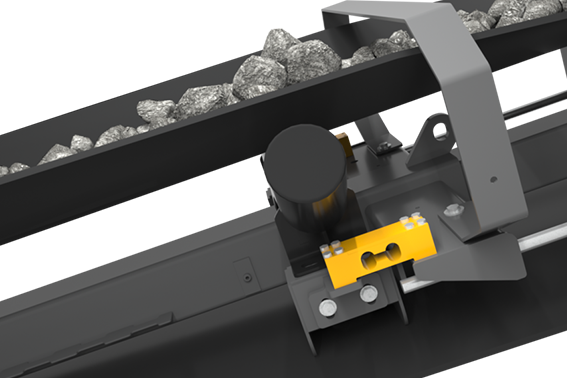

Pan feeder under the crusher

The pan feeder under the crusher is installed for applications involving industrial demolition and highly abrasive rock. It can be easily be removed from the front and is available with a smooth belt on the discharge conveyor.

Lighting package

With additional floodlighting, you have sufficient light to work safely even at dawn and dusk. The lighting package Plus includes the lighting mast, engine compartment lighting and periphery lighting as well as warning lights.

Magnetic separator

The short distance from the crusher outlet to the magnetic separator avoids blockages and, thanks to the strong permanent magnet, metal is removed from the crushed material.

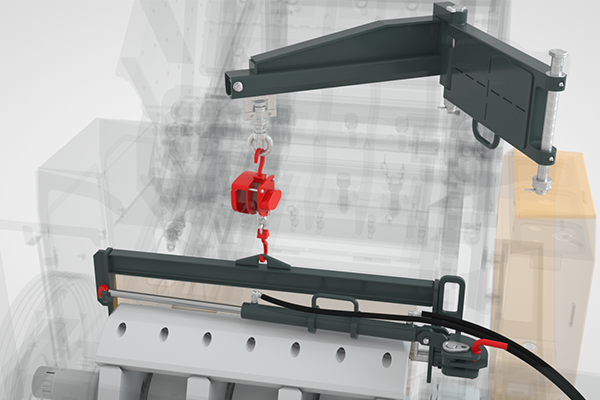

Hammer changing device

Using the hammer changing device including lifting hoist you save time and money and increase safety when changing over hammers on your mobile crusher.

Hammer holder

With this holder you can always have a replacement set of hammers available on-site. The holder provides space for two replacement hammers directly on the machine.

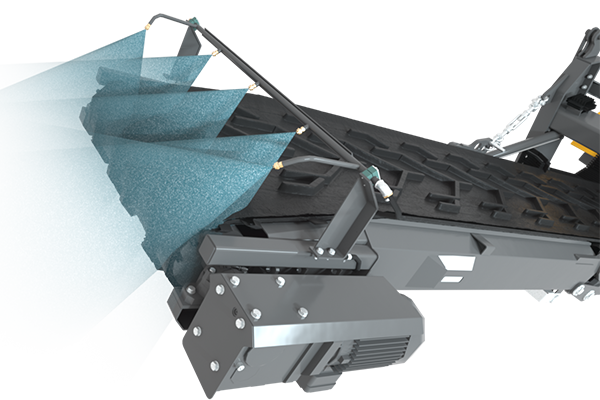

Dust suppression system

Thanks to the dust suppression system you can reduce dust emissions and increase acceptance of the mobile crusher when operating in residential areas.

Integrated fuel filling pump

Thanks to the integrated filling pump including hose, overflow switch and automatic switch-off system you no longer need an external pump to fill up.

Case Studies

Highest quality of end aggregate with RM 120X

Australian company NTEX is specialized in resource recovery. Following the desire to stand out and get the best out of their work, NTEX acquired a RUBBLE MASTER crusher, RM 120X. Find out why it was a game changer and a great success for the company.